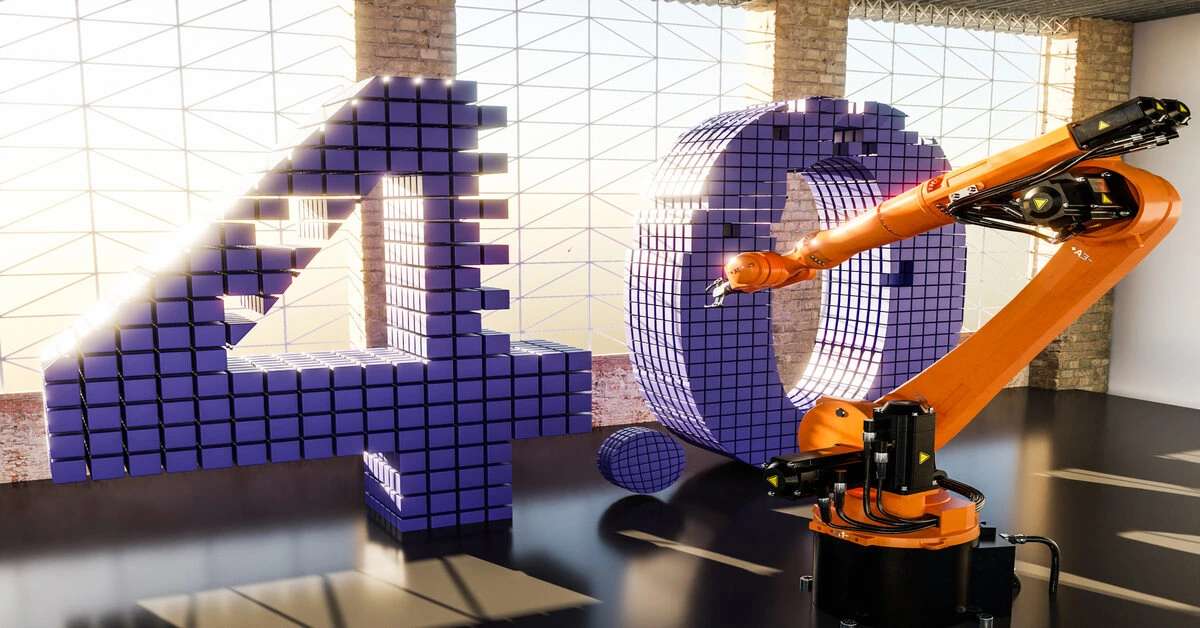

In the era of Industry 4.0, smart manufacturing is reshaping the traditional production landscape, introducing advanced technologies that revolutionize efficiency and precision. One such groundbreaking concept is end-to-end traceability, amplified by the integration of Artificial Intelligence (AI). This blog explores the transformative power of combining end-to-end traceability with AI throughout the entire manufacturing process.

Understanding End-to-End Traceability with AI

End-to-end traceability, coupled with AI, signifies a paradigm shift in manufacturing. It involves the seamless integration of AI-driven systems to monitor and analyze data across every stage of production, from raw material acquisition to the delivery of the final product. This integration empowers manufacturers with unprecedented insights and decision-making capabilities.

The Dynamic Duo: Benefits of End-to-End Traceability and AI Integration

Predictive Maintenance

AI algorithms, when integrated into end-to-end traceability systems, can predict potential equipment failures. By analyzing real-time data from machinery, manufacturers can schedule preventive maintenance, minimizing downtime and optimizing production efficiency.

Quality Assurance through Machine Learning

AI’s machine learning capabilities enable the identification of patterns and anomalies in production data. This translates into enhanced quality control as AI algorithms can detect deviations from expected standards, facilitating quick interventions to maintain and improve product quality.

Supply Chain Optimization

The integration of AI in end-to-end traceability allows for the optimization of supply chain operations. AI algorithms analyze historical data, demand forecasts, and external factors to provide actionable insights, enabling manufacturers to make data-driven decisions for a more responsive and efficient supply chain.

Real-Time Monitoring and Decision-Making

AI’s real-time monitoring capabilities enhance end-to-end traceability by providing instant insights into production processes. This allows manufacturers to make timely decisions, respond to changing conditions, and proactively address issues, ultimately improving overall operational efficiency.

Adaptive Production Planning

AI-driven analytics can dynamically adjust production plans based on real-time demand, market trends, and resource availability. This adaptability ensures that manufacturing processes are aligned with market demands, reducing waste and optimizing resource utilization.

Enhanced Data Security

As data becomes a cornerstone of smart manufacturing, AI-powered cybersecurity measures can be integrated into end-to-end traceability systems. This ensures the protection of sensitive production data, mitigating the risks associated with cyber threats.

Conclusion

The synergy of end-to-end traceability and AI in smart manufacturing heralds a new era of efficiency, agility, and innovation. Manufacturers embracing this dynamic duo gain a competitive edge by harnessing the power of data-driven insights, predictive capabilities, and adaptive decision-making. As smart manufacturing continues to evolve, the marriage of end-to-end traceability and AI not only streamlines production processes but also sets the stage for a more resilient and sustainable future. In a world where precision and efficiency are paramount, this combination is the driving force behind the factories of tomorrow.