About Machine

Condition Based Monitoring & Maintenance

Predictive Insights, Preventive Success: Embracing Monitoring Excellence

About Condition Monitoring

Overview

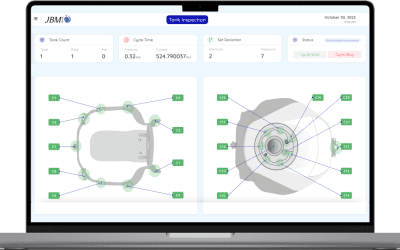

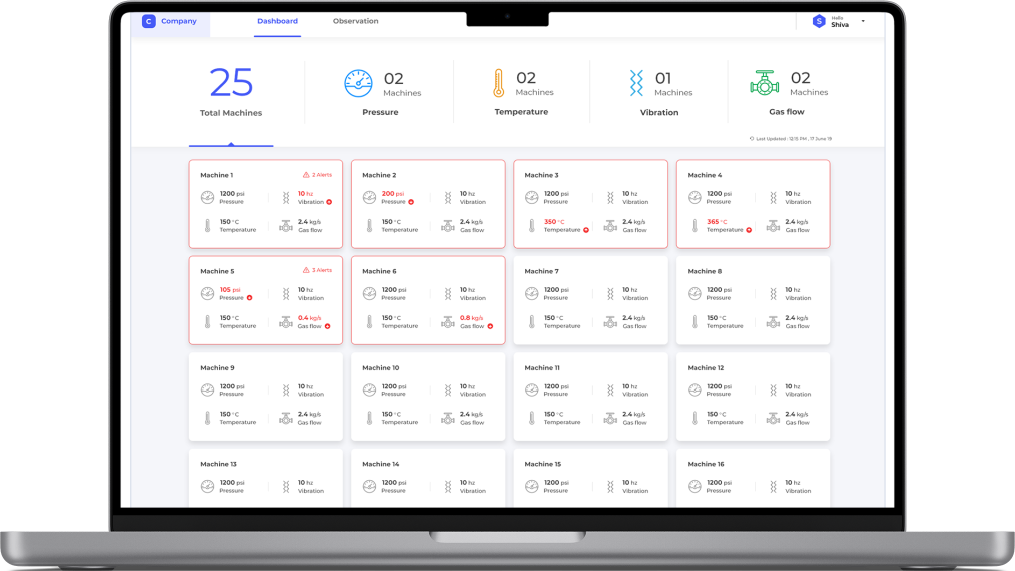

Condition-Based Machine Monitoring Solution is a comprehensive and intelligent system designed to provide real-time insights into the performance of machines and production lines.

It empowers organisations with valuable data, analytics, and visualization tools that enable data-driven decision-making, proactive maintenance, and continuous process improvement.

By harnessing the power of advanced sensors, data analytics, and machine learning, our solution offers real-time insights into the condition of your assets, enabling you to take proactive measures and prevent costly failures before they occur.

What We Have Faced

Challenges

Industries across various sectors face a wide range of challenges. These challenges can vary depending on the industry and its specific circumstances, but some common challenges faced by industries include:

Higher Maintenance Costs

High costs due to no predictive alerts

Ineffective Maintenance Planning

No maintenence schedule or plan

Inability to Optimize Operations

No predictive maintenance alerts on processes

Know More About

Solution Capabilities

Condition Based Monitoring solution has the following features like:

Preventive maintenance

Anomalies detection

Proactive maintenance scheduling

Optimization of spare part inventory

Predictive maintenance

Analytics and real-time data

Know More About

Value Delivered

Reduced downtime

Elimination of unplanned failures

Decreased maintenance costs

Increased asset life

Reduction in collateral asset damages

Ease in prioritization & planning of work orders

Contact Us

Hey! Are you facing the same industry challenges in your organisation? We can help you digitize and transform your challenges and problems into potential digital solutions.

Talk to our experts to know more about our products and solutions.

Others

Machine Solutions

Featured

Case Studies

Vision Inspection of Part Hole and Pocket Count Detection

Our Vision Inspection solution delivers value by significantly improving product’s quality and reducing cycle time by vision inspection of automotive parts and components.

Vision Inspection of Cross Car Beam (CCB)

Our Vision Inspection solution delivers value by significantly improving product’s quality and reducing cycle time by vision inspection of automotive parts and components.

Digital Quality Inspection Solution for Auto Parts Manufacturing

Our digital quality inspection solution for auto parts manufacturing delivers high accuracy while enhancing production efficiency, using computer vision and artificial intelligence