About Industries

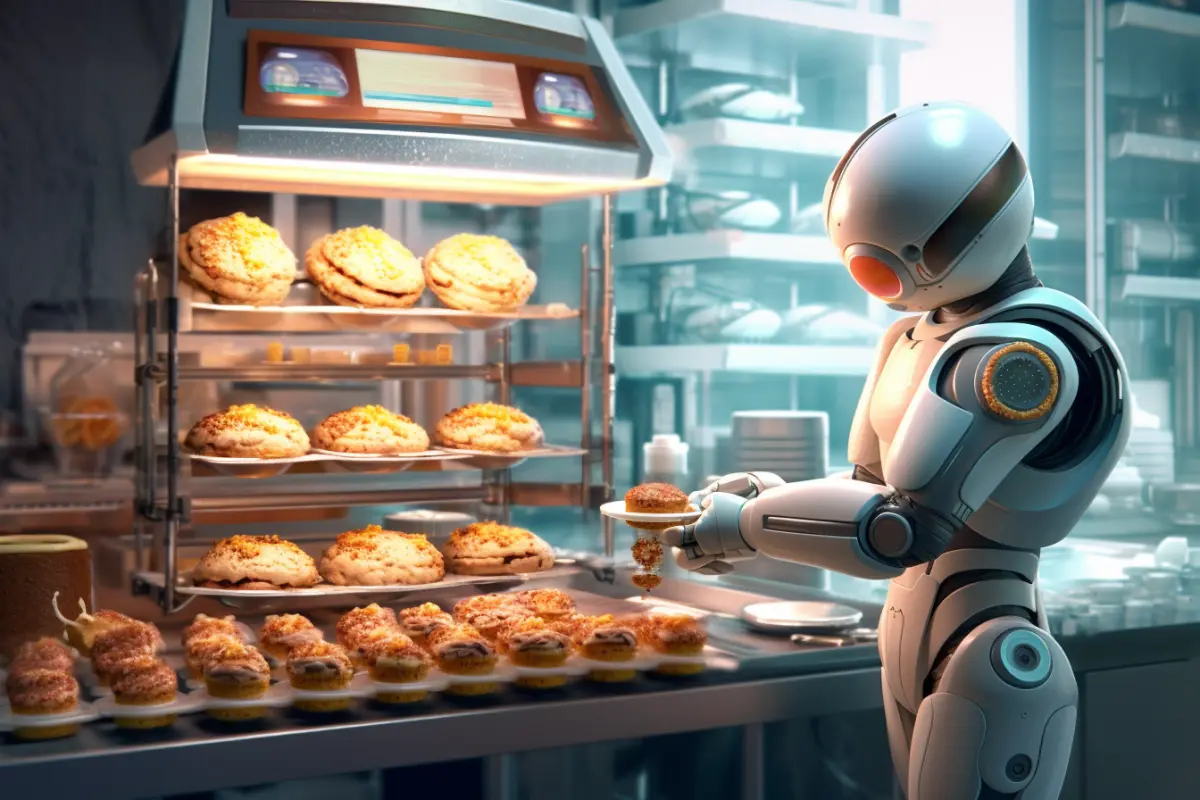

Food & Beverages

Smart Taste, Savvy Choices: AI Revolutionizing Food and Beverages

About Food & Beverages

Overview

The diverse landscape of AI solutions in the food and beverages sector, shed light on the transformative potential they hold for manufacturers, distributors, and consumers.

By harnessing the capabilities of AI, the industry can not only gaining a competitive edge but also striving towards a more sustainable and health-conscious future. From farm to fork, AI is shaping the way we interact with food and beverages, presenting a tantalizing prospect of a tastier, more sustainable, and technologically advanced culinary landscape.

The application of AI in this domain goes beyond simple automation; it delves deep into data-driven insights and pattern recognition, enabling companies to optimize production processes, enhance quality control, and minimize waste. Moreover, AI-powered systems can analyze consumer preferences, leading to the creation of personalized food experiences and tailored nutritional recommendations.

Quality Inspection

Contamination and quality inspection of food are critical aspects of ensuring food safety and consumer health. Proper inspection helps identify and prevent potential hazards that could arise from contamination, spoilage, or other quality issue

Worker health and safety

Contamination and quality inspection of food are critical aspects of ensuring food safety and consumer health. Proper inspection helps identify and prevent potential hazards that could arise from contamination, spoilage, or other quality issues. Also, Vision-based system to monitor the usage of personal protective equipment (PPE) in a food and beverages factory for worker’s safety and health.

Machine Utilization & Productivity

Asset traceability in food manufacturing refers to the ability to track and trace various assets, such as raw materials, ingredients, equipment, and finished products, throughout the entire production process. This includes raw material tracking, batch and lot numbers, inventory management etc.

Sorting and Counting

Automated sorting and counting in food manufacturing is a crucial process to ensure product quality, safety, and efficiency. It involves the use of various technologies and systems to sort and count food items accurately like Weight-based Sorting, Colour and Size Sorting, OCR, Barcode Scanning etc.

Contact Us

Hey! Are you facing the same industry challenges in your organisation? We can help you digitize and transform your challenges and problems into potential digital solutions.

Talk to our experts to know more about our products and solutions.

Featured

Case Studies

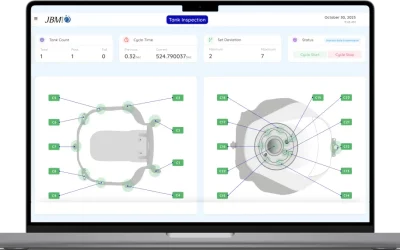

Vision Inspection of Part Hole and Pocket Count Detection

Our Vision Inspection solution delivers value by significantly improving product’s quality and reducing cycle time by vision inspection of automotive parts and components.

Vision Inspection of Cross Car Beam (CCB)

Our Vision Inspection solution delivers value by significantly improving product’s quality and reducing cycle time by vision inspection of automotive parts and components.

Digital Quality Inspection Solution for Auto Parts Manufacturing

Our digital quality inspection solution for auto parts manufacturing delivers high accuracy while enhancing production efficiency, using computer vision and artificial intelligence