About Material

Traceability Solution

Unlock Transparency and Trust with Material Traceability

About Traceability

Overview

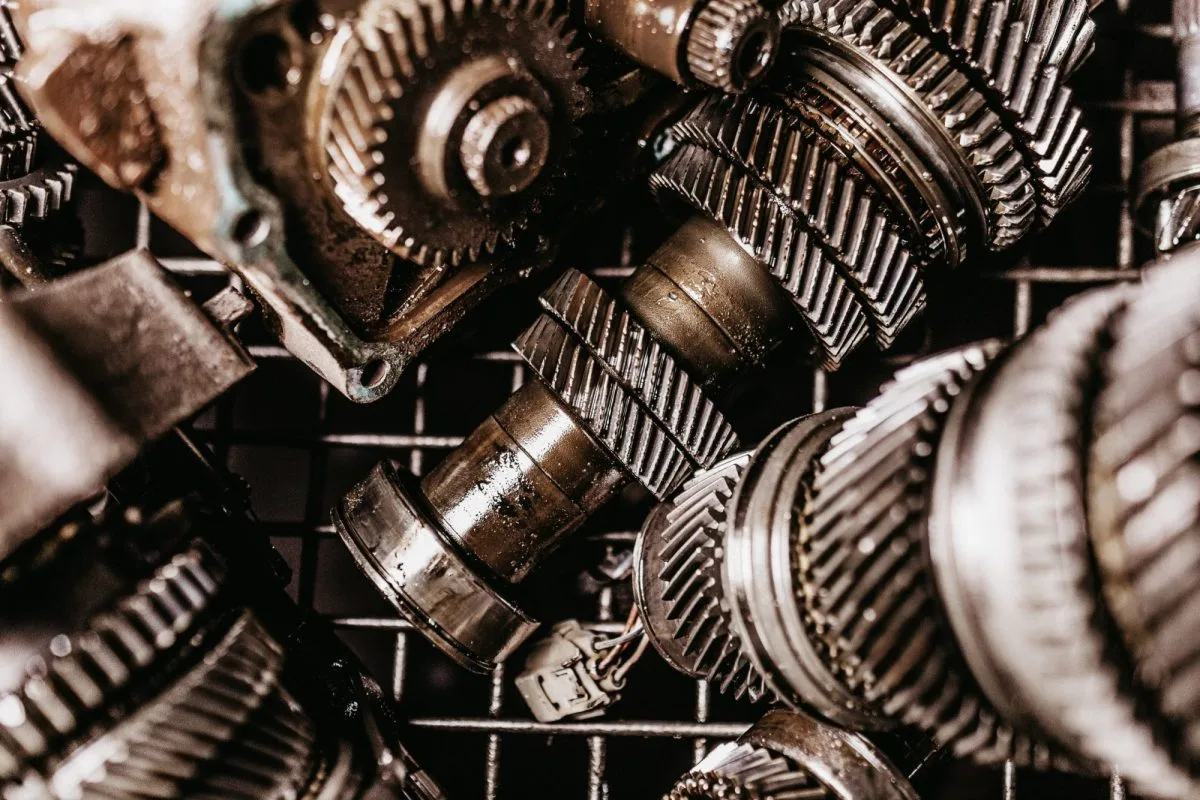

Our IOT based end-to-end raw material to finished good traceability solution is a comprehensive system that allows manufacturers to track and document the entire lifecycle of a product or component, from the initial raw materials to the final customer usage.

It ensures transparency, quality control, compliance, and efficiency throughout the manufacturing and supply chain processes. Our smart system traces location, status, maintenance schedule, and other important information about your organization’s physical assets.

What We Have Faced

Challenges

Industries across various sectors face a wide range of challenges. These challenges can vary depending on the industry and its specific circumstances, but some common challenges faced by industries include:

Data quality and accuracy

Data received and processed is not accurate

Inaccurate material traceability

No visibility on material check and tracking

No visibility on machine parameters

Important machine parameters cannot be tracked

Know More About

Solution Capabilities

Traceabilty solution has the following features:

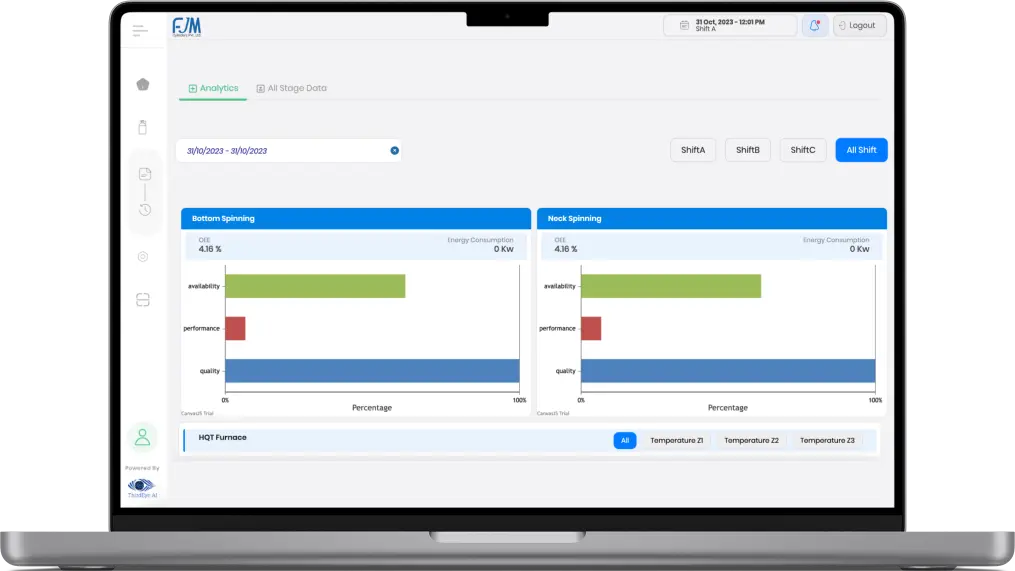

Process parameter monitoring

Asset monitoring at all stages

Material history management

Serial number tracking & tracing

Know More About

Value Delivered

Increased Process Efficiency

Timely Action

Efficient Recalls and Tracebacks

Enhanced Productivity

Supply Chain Transparency

Contact Us

Hey! Are you facing the same industry challenges in your organisation? We can help you digitize and transform your challenges and problems into potential digital solutions.

Talk to our experts to know more about our products and solutions.

Others

Material Solutions

Featured

Case Studies

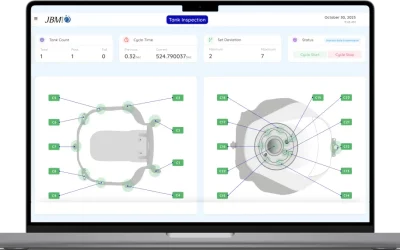

Vision Inspection of Part Hole and Pocket Count Detection

Our Vision Inspection solution delivers value by significantly improving product’s quality and reducing cycle time by vision inspection of automotive parts and components.

Vision Inspection of Cross Car Beam (CCB)

Our Vision Inspection solution delivers value by significantly improving product’s quality and reducing cycle time by vision inspection of automotive parts and components.

Digital Quality Inspection Solution for Auto Parts Manufacturing

Our digital quality inspection solution for auto parts manufacturing delivers high accuracy while enhancing production efficiency, using computer vision and artificial intelligence