This framework offers a structured approach to assessing and optimizing key components of manufacturing, ensuring seamless operations and continuous improvement.

What is 4M in Production?

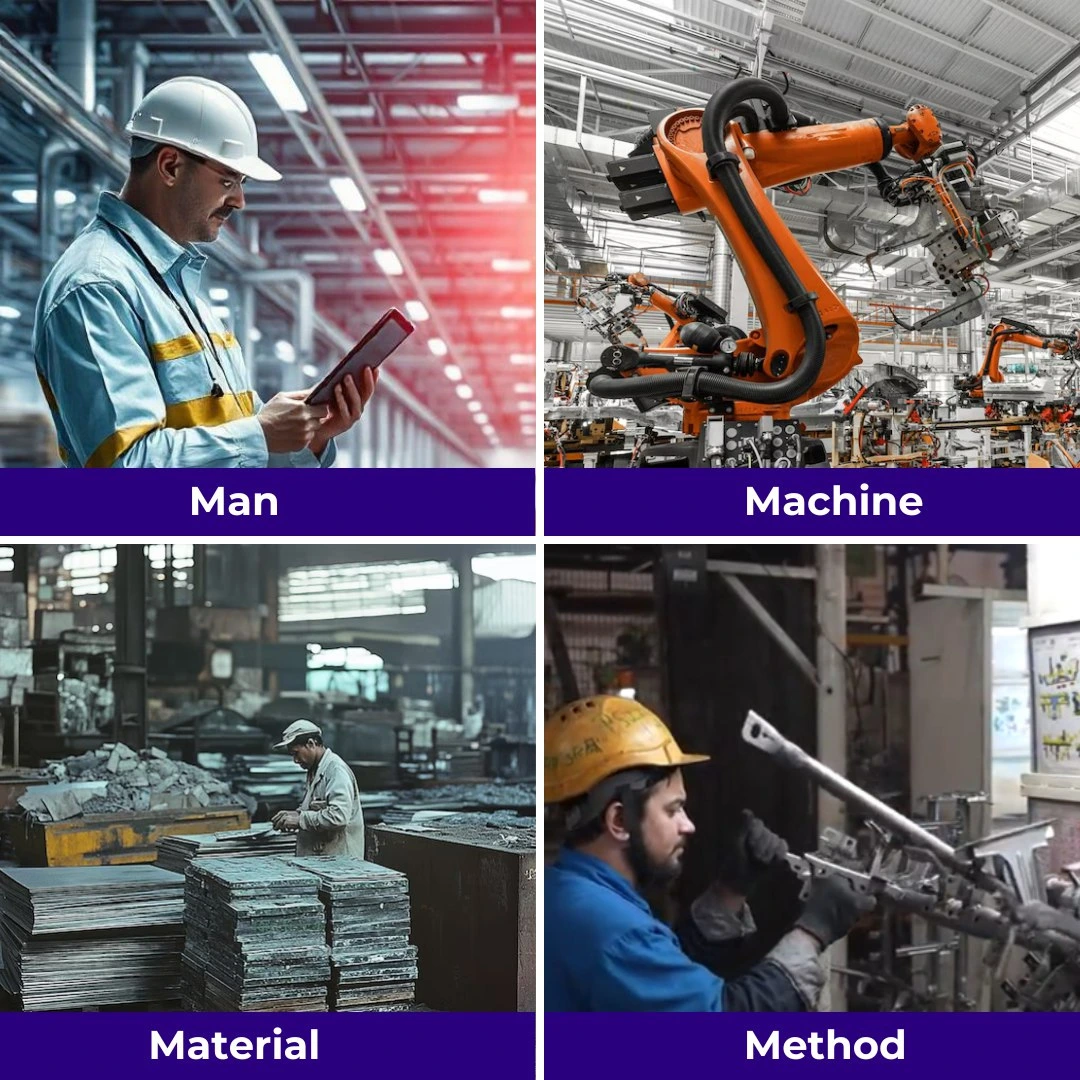

The 4M concept in manufacturing refers to four essential elements that directly influence the production process

Man: The human element, including operators, engineers, and staff, plays a vital role in ensuring tasks are completed effectively and efficiently. Skill levels, training, safety awareness, and motivation all contribute to production outcomes.

Machine: The equipment and tools used in the manufacturing process. Machines must operate at peak performance with minimal downtime to ensure production runs smoothly. Equipment failure or inefficiencies can significantly impact productivity.

Material: The raw materials and components used in production. The quality, consistency, and availability of materials are crucial for minimizing waste and maintaining high product quality.

Method: The processes and techniques used to carry out production. This includes workflow design, procedures, and operational standards. Effective methods lead to higher efficiency, while poorly designed processes can lead to bottlenecks and errors.

Together, these four elements form the foundation of a successful manufacturing operation. By analyzing and optimizing each of these areas, manufacturers can enhance overall performance, reduce costs, and improve product quality.

How to Apply the 4M Rule Effectively in Production

Implementing the 4M analysis is not a one-time activity but a continuous improvement process. Here’s how to apply and improve each element effectively in a production environment

Optimizing Manpower (Man) Skill Development and Training: Regular training sessions help improve workers’ expertise and adaptability to new technologies and processes. This reduces the risk of errors and increases efficiency.

Safety Protocols: Ensuring a safe working environment minimizes accidents, which can cause disruptions in production. A well-trained workforce that understands safety protocols is essential for smooth operations.

Performance Monitoring: Implement feedback mechanisms to regularly assess the performance of employees. Encourage continuous improvement by recognizing achievements and addressing performance gaps.

Maintaining and Enhancing Machinery (Machine) Preventive Maintenance

Schedule regular maintenance checks to prevent machine breakdowns. Early detection of wear and tear saves costs and prevents unexpected downtime.

Technology Upgrades: Stay up-to-date with the latest machinery and technological advancements. Investing in modern, energy-efficient machines can reduce long-term operational costs and boost productivity.

Real-Time Monitoring: Use IoT-based systems or sensors to monitor machine performance in real time. This can help detect abnormalities and allow quick interventions before major issues arise.

Ensuring Material Quality and Availability (Material) Quality Control

Implement rigorous quality checks at different stages of material handling from procurement to production. Ensure raw materials meet required specifications to avoid defects in final products.

Inventory Management: Adopt efficient inventory systems that ensure materials are available when needed without overstocking. This balances production flow while reducing costs associated with excess inventory or stockouts.

Supplier Relationships: Maintain strong relationships with reliable suppliers to ensure a steady flow of high-quality materials. Engage in long-term contracts to reduce uncertainty in the supply chain.

Streamlining Production Methods (Method) Standardize Processes

Develop and implement standard operating procedures (SOPs) that everyone in the production line follows. This minimizes variation and helps maintain product consistency.

Lean Manufacturing

Principles: Adopt lean manufacturing techniques, such as eliminating waste (time, materials, or energy), to improve efficiency. Continuous improvement initiatives like Kaizen can help refine methods over time.

Process Automation: Where feasible, automate repetitive tasks to increase accuracy and speed. Automation can also reduce human error and allow workers to focus on more value-added activities.

Why 4M Analysis is Key to Modern Manufacturing Success

As industries evolve and demand higher standards, manufacturers need to adopt comprehensive frameworks like 4M to stay competitive. The 4M analysis enables manufacturers to:

Boost Production Efficiency: By optimizing manpower, machinery, materials, and methods, manufacturers can significantly increase their output while minimizing waste and costs.

Improve Product Quality: Standardized processes, quality materials, and well-maintained equipment lead to higher-quality products, improving customer satisfaction and reducing returns.

Enhance Flexibility: A well-implemented 4m method allows manufacturers to quickly adapt to changing market demands or new technologies, ensuring they remain agile and competitive in the global market.

Conclusion

The 4M analysis is a powerful tool in manufacturing that helps organizations focus on critical aspects of production- Man, Machine, Material, and Method. By continuously improving each element, manufacturers can boost operational performance, enhance product quality, and achieve sustainable growth. Applying the 4M rule isn’t just about improving isolated areas but understanding how these elements interact and contribute to overall efficiency. When done right, the 4M analysis becomes the cornerstone of a successful and agile manufacturing operation.